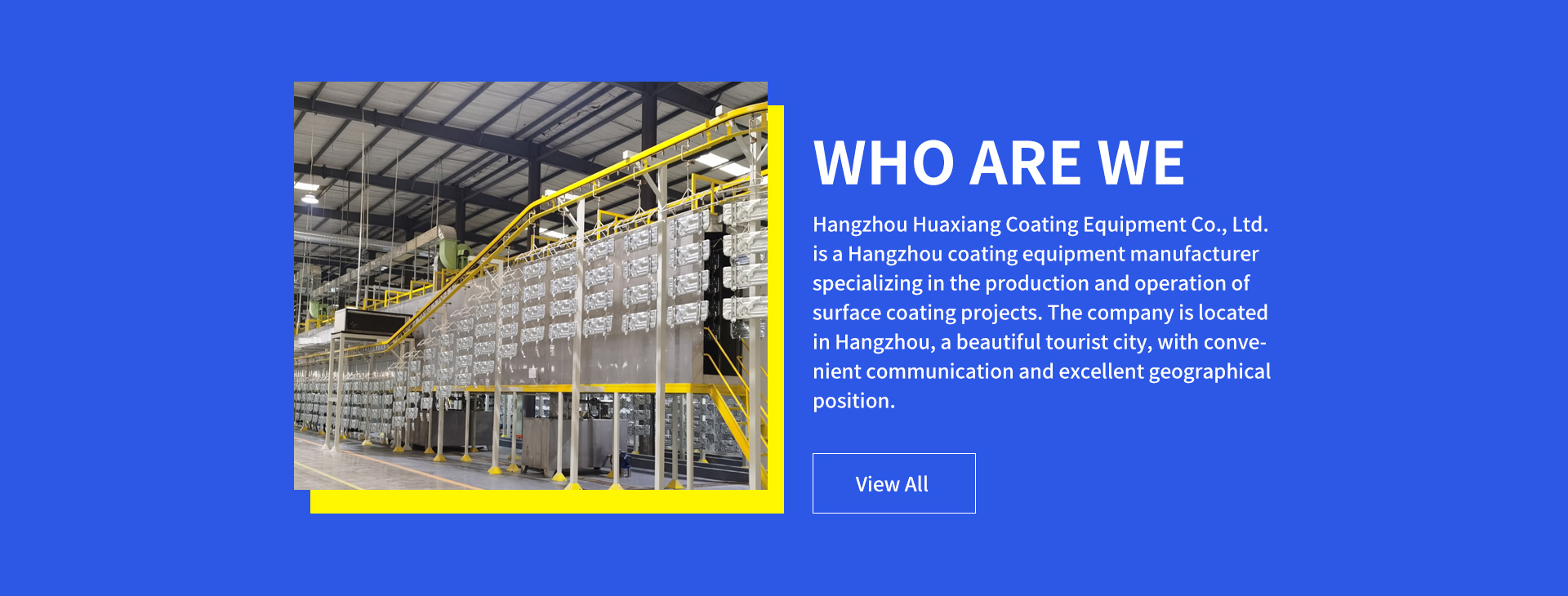

Powder Coating Machine is a revolutionary device in the coating industry. It has transformed the way various objects are coated, offering enhanced durability and aesthetic appeal.

The working principle of a

Powder Coating Machine is based on electrostatic attraction. The machine first sprays positively charged powder particles onto a grounded object. These particles adhere to the surface, creating a uniform coating. Then, the coated object is cured in an oven at a specific temperature. During curing, the powder melts and forms a hard, protective layer.

There are different types of

Powder Coating Machines. One common type is the corona charging system. It uses a corona discharge to ionize the air and charge the powder particles. Another type is the tribo charging system, which charges the powder by friction. Each type has its own advantages and is suitable for different applications.

In terms of application fields,

Powder Coating Machine is widely used. In the automotive industry, it coats car parts such as wheels, bumpers, and chassis. This provides a long-lasting finish that can withstand harsh weather conditions and road debris. In the furniture industry, it gives a smooth and stylish coating to metal furniture pieces, making them more resistant to scratches and wear. It is also used in the manufacturing of household appliances like refrigerators and washing machines, enhancing their appearance and durability.

When it comes to operation, there are several key points. Firstly, proper surface preparation is crucial. The object to be coated must be clean, free from grease and dirt. Secondly, the operator needs to adjust the powder flow rate and spray pressure according to the object's size and shape. For example, a small and delicate object requires a lower powder flow rate and spray pressure compared to a large and flat surface.

Maintenance of a

Powder Coating Machine is also essential. Regularly clean the powder spray gun to prevent clogging. Check the hoses and connections for any leaks. The filters should be cleaned or replaced periodically to ensure proper powder flow. Also, keep the curing oven in good working condition, monitoring the temperature control system.

Common problems with

Powder Coating Machines include uneven coating, which can be caused by incorrect spray parameters or a dirty spray gun. If the powder does not adhere well, it might be due to improper surface preparation or a problem with the electrostatic charging system. To solve these issues, operators need to carefully check and adjust the relevant settings, and ensure proper surface treatment.

In conclusion,

Powder Coating Machine is a valuable asset in many industries. Its efficient working principle, diverse types, wide application range, and the ability to provide high-quality coatings make it an indispensable tool. By following the correct operation and maintenance procedures, users can maximize its performance and enjoy the benefits it brings.

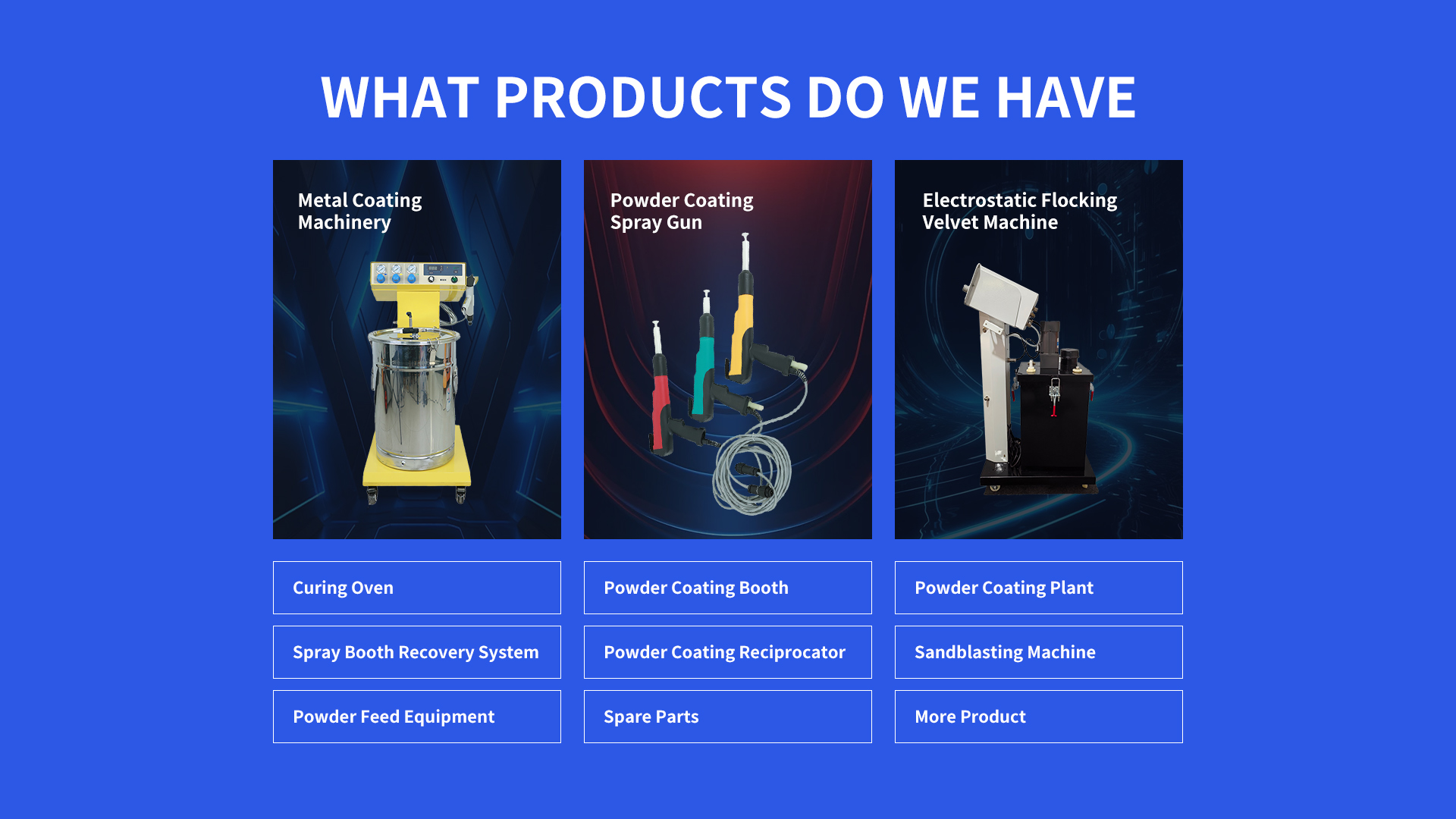

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com